In 2015 EmTech developed their NovaTech range of trolley based multistage incubation systems in order to satisfy the requirements of hatcheries that prefer to use traditional multistage methods of incubation or are looking to expand existing facilities with similar equipment.

Coming from a background of Buckeye and Chick Master Incubator companies we have always been aware of inherent performance issues related with these and similar systems. At EmTech we were determined not to make the same mistakes with the design of our NovaTech range. Consequently, the design concept was very carefully considered, focussing initially on three more obvious weaknesses that impacted on performance: thermal conductivity of the cabinet, turning of the eggs and most importantly, air flow.

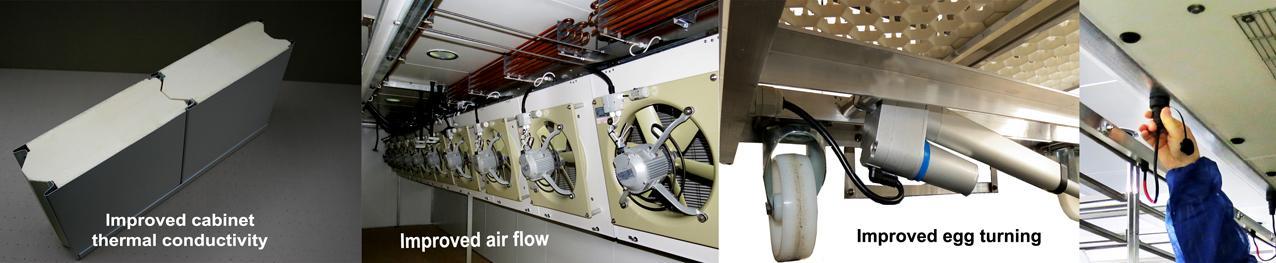

While ensuring that we retained all the proven elements of these systems we started with the design of the incubator cabinet itself. We decided that the well documented inefficient mechanical turning systems should be replaced with IP66 rated individual turning actuators fitted to every trolley. This important change not only provided optimal turning angles for every single trolley, even on uneven floors, but also meant that the cabinet did not have to be strengthened by metal posts placed between every wall and ceiling panel to support the mechanical turning system. This improvement now allowed us to use an interlocking PIR, leak proof insulated cabinet panel that did not suffer thermal leakage and ensured that the internal environment could now be very carefully controlled to within 0.6֯ C – what we call the >EmTech Effect<.

Finally, the overhead fan assemblies were completely redesigned with high capacity fans and a revolutionary new fan-board that increases airflow and pressure by more than 25% over existing systems.

Hatcheries that purchased the NovaTech immediately experienced improvements in hatch performance of up to 1.6% over similarly installed equipment and much improved chick quality, culls and first week mortality.

If hygiene and the ability to efficiently clean and sanitise fixed-rack systems is a concern, it’s worth noting that existing Chickmaster Classic hatcheries can now expand capacity (where space is available) with NovaTech, trolley based, systems.

Now that we better understand the importance of airflow and the influence this has on the even distribution of temperature and gasses across the entire egg pack, we quickly realised that older equipment could also be easily upgraded to receive the same environmental conditioning benefits as the NovaTech.

After conducting extensive trials on older Buckeye and Chickmaster Classic models by replacing existing fan boards with the EmTech standard fan board assembly, we have found that the hatch performance had improved by a remarkable 0.5 – 1.5%, depending upon model and age.

Today, hatcheries in UK, Canada, Japan, Pakistan, Indonesia and elsewhere that have invested in EmTech NovaTech systems and our range of upgrades, are now seeing much improved capacity and performance for a relatively low investment cost.

Why not talk to our sales team to find out how EmTech can help to improve your profitability?