Energy Efficiency is something that affects your bottom line almost as much as the quality and quantity of your chicks but is often not taken very seriously or even ignored.

While many manufactures focus purely on chick quality and hatchability the success of the >EmTech Effect< has allowed EmTech to take the next step and explore the greater savings and return on investment that can be gained from achieving significant energy efficiencies.

There are two areas of potential hatchery energy efficiencies that all incubator suppliers should look at: 1) incubators, and 2) supporting services such as ventilation, heating and cooling.

Let us first look at incubators. We know that they need electricity for turning the fans but there are energy efficiency opportunities to be gained even here. At EmTech we use Frequency Drives as standard on our setters to match the air flow with any particular stage of incubation and also to drive the forward and reverse fan direction to effectively minimise temperature bandwidth to no more than 0.6° C.

Incubator heating is also an area where huge efficiencies can be made. Because EmTech’s highly sealed cabinets have no metal supports to negate thermal bridging we only require power at start-up for 6.5 hours. Once the incubator comes up to temperature heating is not required again until the next eggs are loaded in 18 days. Compare this to hot water heated systems where the customer not only has an initial high capital investment in boilers but a heat distribution system that needs to run 24/7.

Now we can look at incubator cooling. Because EmTech employs large capacity cooling coils with a greater surface area than any other system on the market we can run our cooling water at a 2-4⁰C higher than other systems. This vastly improves the COP (coefficient of performance) of the water chillers resulting in significantly reduced energy costs.

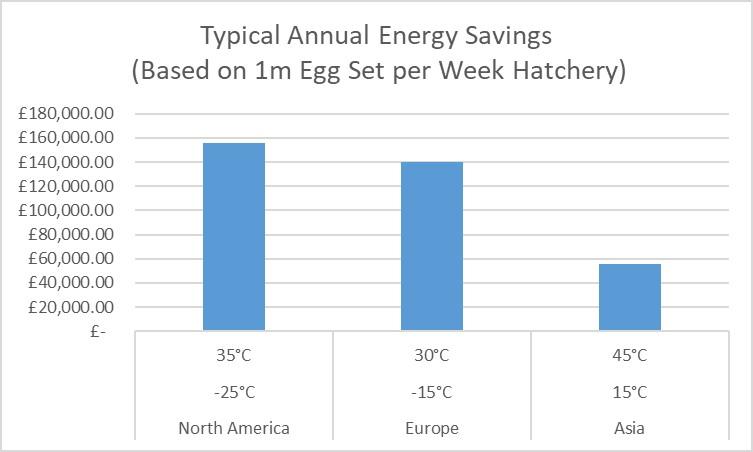

Supporting Services is also an area where EmTech also has an enormous breadth of experience. EmTech’s Primary Heat Recovery System gives you the ability to warm the hatchery air free of charge, either in cold climates or following de-humidification. Our hatchery Heat Recovery systems are designed and calculated on the heat output of the incubators and can be installed in most hatcheries. The core principle of these systems is that we capture the embryonic heat given off by the developing embryos in the chilled water-cooling system and use this heat through specially designed coils to heat the incoming air that the hatchery requires. This system has a huge potential for energy savings and furthermore, reduces the cooling load on the chillers. With these major benefits, coupled with variable flow for both the chilled water and ventilation systems, it can result in a 25-40% annual energy costs. Please see the graph below to see the enormous potential of our EmTech systems.

For more details and quotations please contact:

EmTech Hatchery Systems

www.emtech-systems.com