EmTech offers a highly efficient parts service for all their incubation and ventilation equipment, as well as a range of spare parts for Chick Master, Buckeye, Newmark and Western fixed-rack setters.

For older equipment, as long as we have a sample of the original part it is usually no problem. EmTech will reproduce to the same (or better) specification.

Examples of featured spare parts offered by EmTech:

- Original EMS communal turning actuator for the Chick Master AVIDA setters.

- Original EMS communal turning actuator for the Chick Master Buckeye multi-stage setters.

- Setter and Hatcher door seal, handle and hinge kit – by door – original parts.

- Paddle Fan Centre Hub Welded assembly (SPIDER) for hatchers and single-stage setters.

- Replacement Paddle Fan blades – 144 and 216 sizes offered in the new EmTech profile design for improved airflow and temperature bandwidth.

- Hatcher Auxiliary Fan – 160mm or 200mm system – can be retrofitted to old Buckeye and CM hatchers – 3 speed adjustable.

- Ex stock CQM1 OC222 relay cards

Upgrades

Many of the features we build into our systems as standard are also available as upgrades to improve existing installed equipment. In other words, older machines can be updated to the latest standard for a fraction of the cost of a new machine. Some of our upgrade options include:

Turbo-Set & Turbo-Hatch

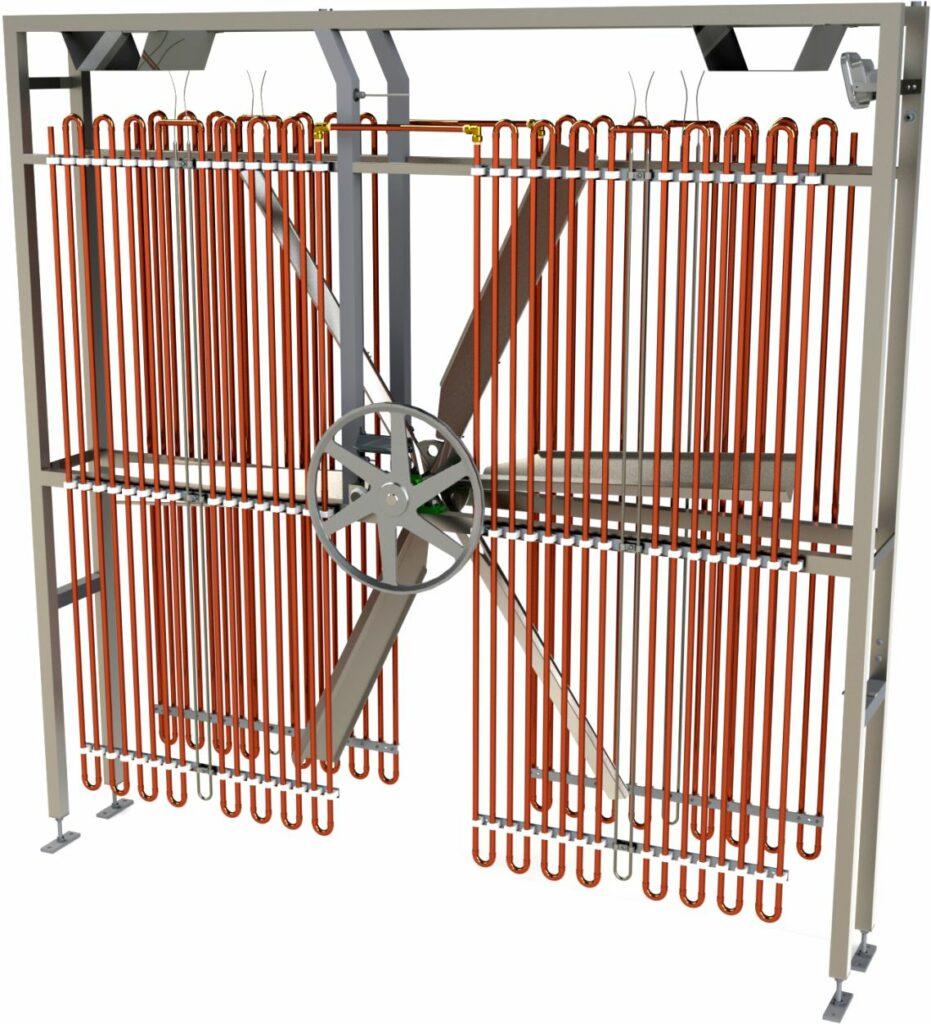

SINGLE-STAGE REPLACEMENT FAN FRAME SYSTEM

For improving the structure, fans, cooling, humidity and air delivery on Avida setters and hatchers.

The most efficient cooling system on the market today without the need to replace your entire setter or hatcher. A full 16 laterals allow the customer to run 17°C (62.6°F) chilled water temperatures while controlling airflow accuracy.

Download our Turbo-Set / Turbo-Hatch brochure

Mini-Turbo VF

APPLIED MODERNIZATION FOR THE VF HATCHER

Our popular Turbo-Hatch concept is now scaled for use in vertical fan-frame hatchers to radically improve performance.

Download our Mini-Turbo brochure

T3 Cooling Upgrade

A triple flow cooling upgrade for Chick Master Classics

With 24V and dual-valve cooling per section that guarantees a 17°c water operating temperature.

When your eggs are getting hot and temperatures are out of balance, give them the “T3” cooling from EmTech.

Download our Cooling Upgrade brochure

Turn-Plus Classic Turning Upgrade

Distributed turning ensures uniformity, and assures the user that correct embryo agitation is taking place.

With the “Turn-Plus” your angles are consistent and correct from set to transfer, and prevents inconsistent airflow throughout the machine.

Download our Turning Upgrade brochure

Fan-Board System Replacement Upgrade

EmTech’s powerful fan-board assembly as supplied in the NovaTech range is now available as a retrofit for many types of multi-stage fixed rack setters and multi-stage trolley setters including Buckeye and Classic models.

A highly effective upgrade for improved energy efficiency.

The improved airflow significantly enhances the setter temperature bandwidth.

Download our Fan-Board brochure

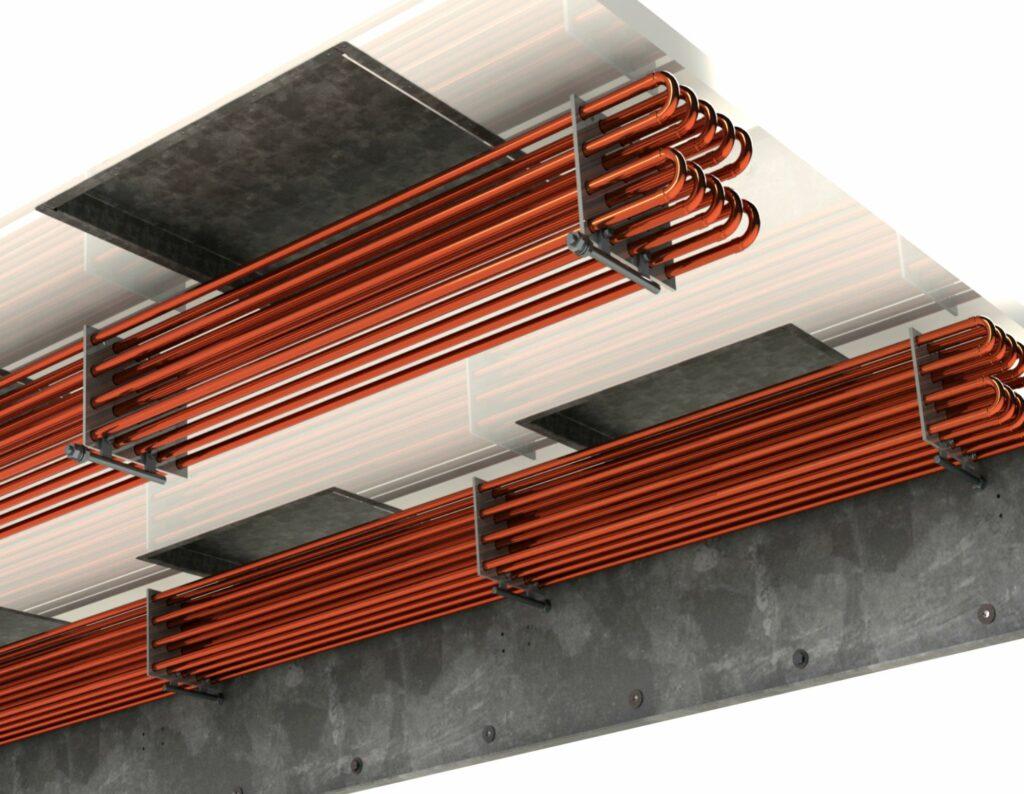

Cooling Coil Upgrade

EmTech offers a cooling coil upgrade for all Buckeye and Chick Master setters and hatchers.

Many of the older hatchers and SS series setter models have an insufficient cooling capacity and can struggle with the greater embryonic heat output from today’s breeds.

The new EmTech cooling coil has a significantly greater cooling capacity than most systems on the market with parallel vertical columns as compared to only 12 vertical columns with the latest Chick Master coil. Compared to the older Buckeye 150 hatcher, the new EmTech assembly has over three times the capacity.

Improved Temperature Control and Chick Quality

EmTech’s highly efficient cooling coils reduce the problem of chick fluff collecting on the coil, therefore, removing the need to clean the fluff from the coil to maintain cooling capacity. The new coil can also operate perfectly well with higher temperature cooling water.

EcoMist™ Humidity System

EmTech’s Humidity System mixes water and compressed air through an atomiser to produce a vapour like mist.

EcoMist™ is reliable and economic to use and available to replace humidification systems in almost any setter or hatcher.

Acu-Turn System – 24VDC Trolley Actuator

A safe, cost-effective replacement for the GC84 230VAC electrical actuator

EmTech is aware of the safety and maintenance issues regarding the GC84 230VAC electrical actuator used in older Buckeye and Avida setters. Servicing and replacing these actuators has also become increasingly more difficult as prices rise, and lead times lengthen.

All setters in the EmTech products range have been developed to operate using a 24VDC actuator. This actuator is completely safe, easy to install and is now available as a retrofit to replace the GC84 230VAC unit. The advantage of the EmTech 24VDC actuator is that it is IP66 rated and can withstand pressure washing. The system is also fully compatible with Genesis 2 and Genesis 3 controls that operate with the Turn Trolley identification and failure system.

Download our Actuator brochure

Setter Trolley Upgrade Options

EmTech offers a complete refurbishment service for Buckeye trolleys to restore them to the latest standards of performance, safety and operational efficiency.

- Stainless steel tray frames replaced as necessary – all frames stripped and replaced with new rivets.

- Stainless steel top and bottom turning bars.

- 24VDC actuator.

- Top and Bottom cross members with replacement IGUS plastic bearing housing.

- New hangar bars running on IGUS plastic bearings, plus bushes and castors where necessary.

Farm Trolley

EmTech manufacture new farm trolleys built to a high quality and specification. Main features include:

- Aluminium frame

- 14, 16 or 18 deck

- Depth to fit most tray types

- Stainless steel or aluminium runners

- Supplied with or without tray locking

Control System Upgrades

EmTech can offer a cost effective upgrade as a solution for the now obsolete Omron CQM1 series PLC and modules using the CJ platform. This economical upgrade only replaces the PLC components while still utilizing the main control switchgear.

EmTech also offers solutions to replace entire existing incubator and hatchery control systems regardless of the make of incubator or control system employed, whether it be Buckeye Aces or electromechanical, for example.

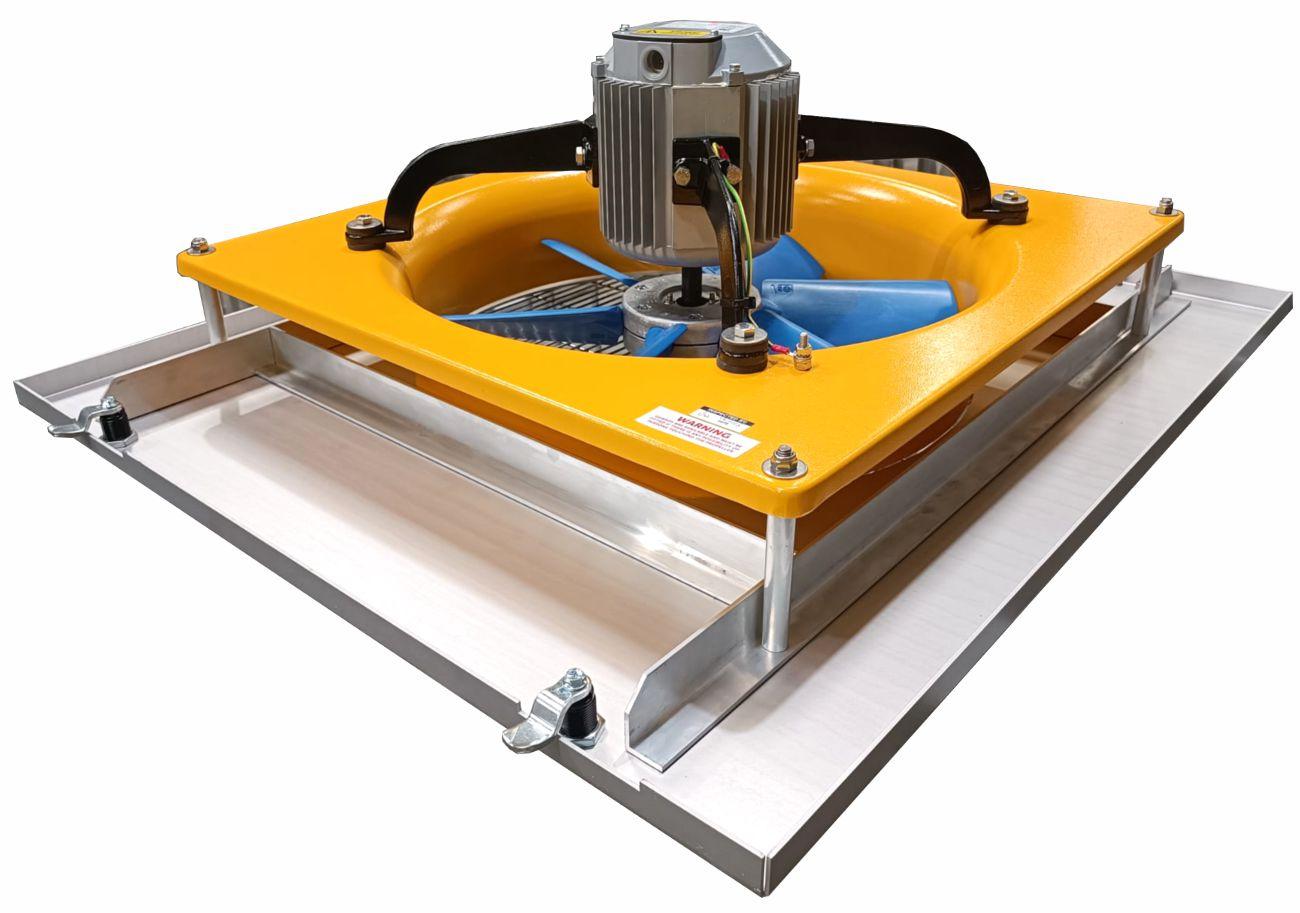

Hatcher Plenum Exhaust Kits

EmTech offers a complete solution for the installation of Hatcher plenums. The Kit includes: panels, exhaust fan, standalone fan speed controller and pressure sensor.

For Hatcheries requiring an automated pressure control system utilising their existing installed plenums, EmTech can offer a solution that comprises: pressure control kit with exhaust fan, standalone fan speed controller and pressure sensor.