Over many years considerable effort has gone into maximising operational and energy efficiencies throughout the entire incubation process. So much so that today new innovations rarely make more than fractional differences. EmTech Hatchery Systems, however, has identified one particular aspect of incubator design that has seemingly received very little attention, namely the design, efficiency, and thermal conductivity of incubator cabinets.

Typically, incubator wall panels are constructed of a 42mm, high-density, expanded polystyrene (EPS) core with a plastic, fibre-reinforced, outer sheeting. This gives a thermal conductivity rating of around 0.029 W/Mk. While this is perfectly good for insulation purposes it is important to understand that a typical incubator cabinet is built with a framework of integral aluminium extrusions to retain the panels and provide support and rigidity. Now, we know that aluminium is an excellent conductor of heat and by providing this thermal bridge at regular intervals throughout the entire cabinet the insulation properties of the incubator can be severely compromised as valuable heat is transported away from where it is required. This ‘thermal leakage’ can often result in unwanted localised condensation, cold spots and energy losses, inhibiting the ability to accurately control air temperature inside the incubator. For single-stage setting a fully insulated cabinet is especially important to prevent heat loss, particularly during the early (endothermic) stages of incubation.

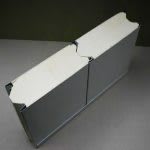

Having conducted rigorous field trials and with the help of thermal imaging cameras EmTech’s design team believe that they have made significant improvements in this crucial area of incubator design. Uniquely, EmTech incubator cabinets do not require an aluminium or steel framework. All wall and roof panels utilise interlocking joints – a construction method that provides all the strength necessary to support the structure.

Furthermore, the panels have a 50mm PIR (polyisocyanurate) insulated core with food-safe, steel, outer sheeting (stainless-steel internally in hatchers).

This gives a typical thermal conductivity rating of 0.021 W/Mk, an impressive 38% better than the typical EPS panel.

Another major advantage of the PIR core is that it is Fire Rated. This not only provides obvious health and safety benefits but insurance reductions and little need for sprinkler systems.

We all know that an even temperature distribution throughout the entire egg mass is the key to producing top quality DOC’s. EmTech systems, with the combination of excellent insulation, air-flow, and a tight temperature bandwidth, ensure an enhanced hatch-window for improved chick quality and maximum hatchability with the added benefit of lower energy bills.