At EmTech, we pride ourselves on great design with an honest approach. ‘zero-point-six’ is the superior quality and quantity of the chicks hatched from EmTech setters and hatchers. It may sound like a marketing ‘gimmick’ but it’s certainly not. Recent results have shown exceptional improvements in chick numbers, 7-day mortality and FCR. Just ask our customers!

Why 0.6°?

EmTech systems provide a temperature bandwidth (difference) of no greater than 0.6°C within the egg mass. The benefit is that all the developing embryos experience exactly the same environmental conditions so that they all hatch within a very short window. EmTech systems are proving every day that the tighter the hatch window the better the quantity, quality and liveability of the chicks, and the best indicator that you have got it right – simple as that.

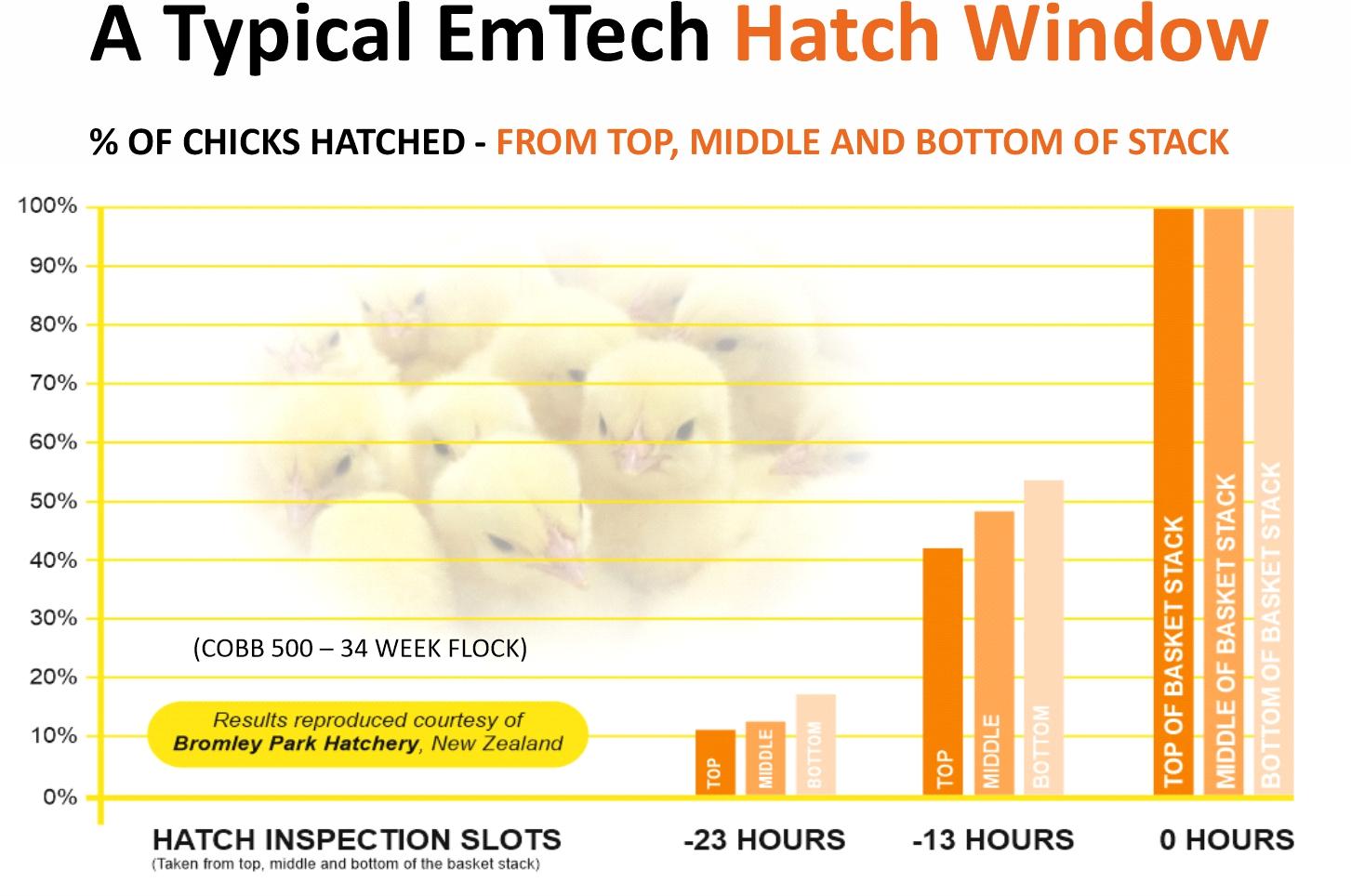

Hatch window (for % eggs hatched)

This graph shows the typical hatch window and while similar to % of hatch spread, represents the accumulative number by percentage to show the % of chicks hatched from the entire egg mass from the onset of piping. The very tight temperature controls result in a condensed hatching period. Typically, from EmTech incubators this is less than 24 hours but the majority hatch within a 12-hour period.

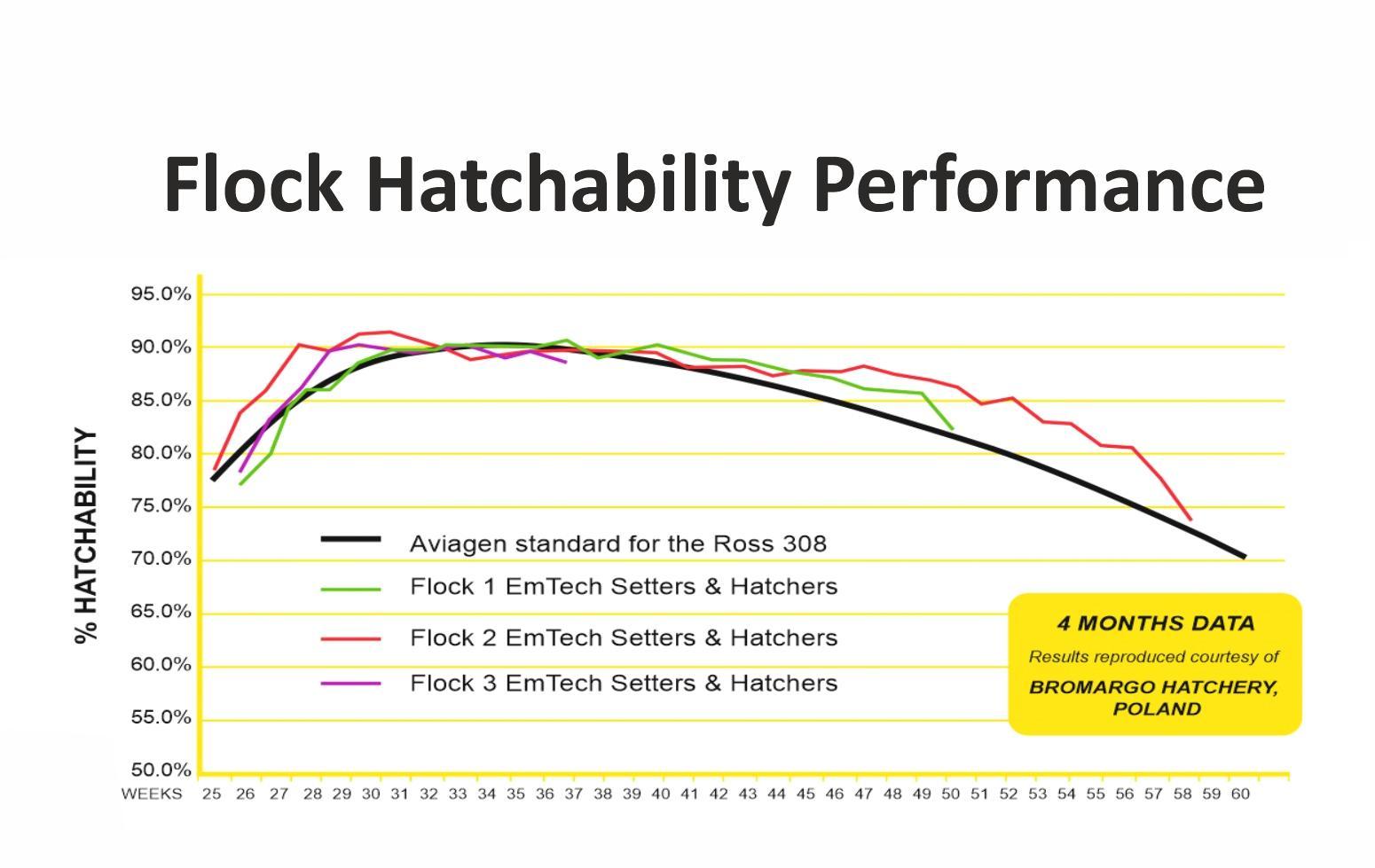

Flock Hatchability Performance

Based on four months data from the BroMargo Hatchery in Poland, this graph shows the performance of EmTech single stage setters and hatchers over three flocks compared with the Aviagen standard performance for Ross 308. As you can see, the results are excellent, especially in the early and late flocks where many other incubation systems struggle to reach target figures.

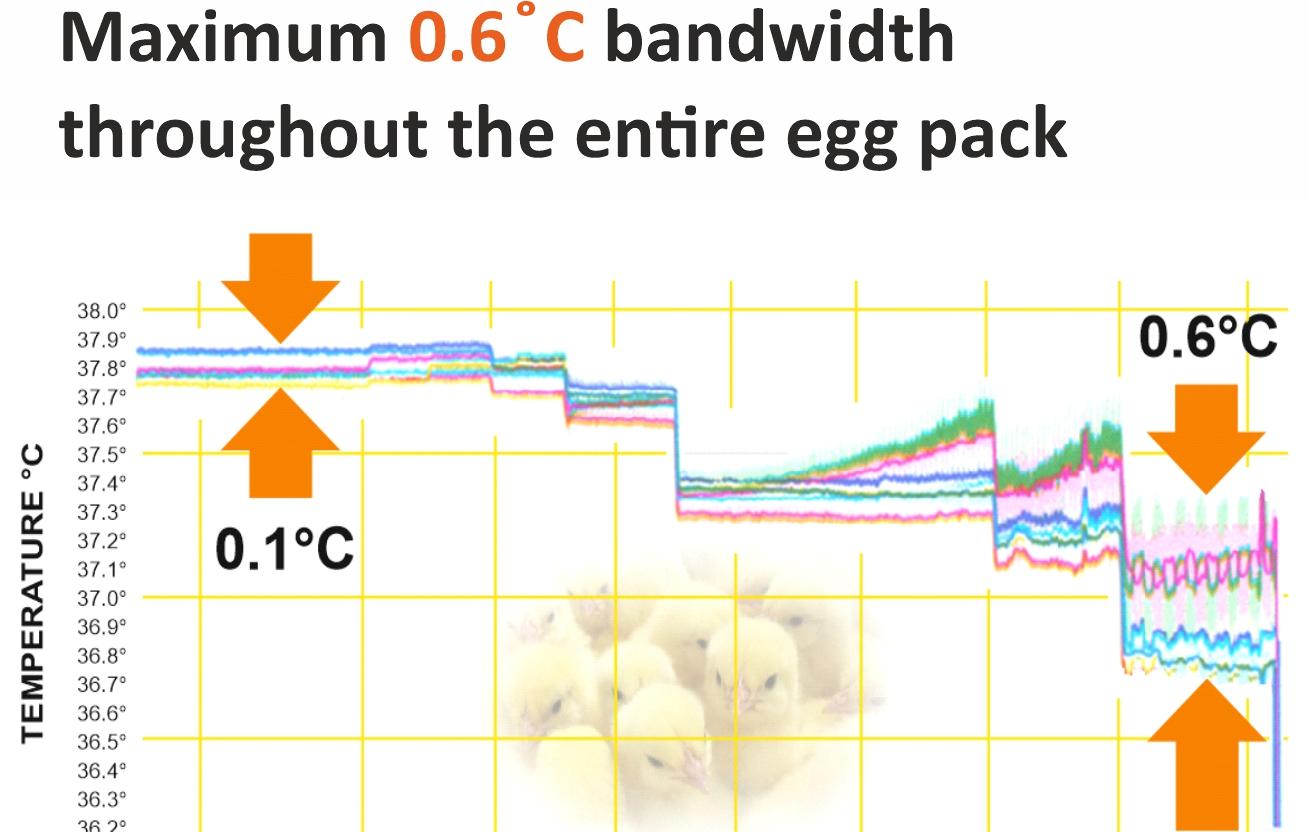

Temperature Bandwidth

The above graph shows the very tight temperature spread of the air surrounding the egg mass – what we call the ‘temperature bandwidth’. The bandwidth is around 0.1°C early in the single-stage process but quickly increases as the embryos develop. EmTech’s well sealed cabinet and optimum airflow facilitates correct moisture loss and heat transfer from the egg mass while ensuring the bandwidth never exceeds 0.6°C. The result is well conditioned, unstressed chicks that hatch in a tight window.

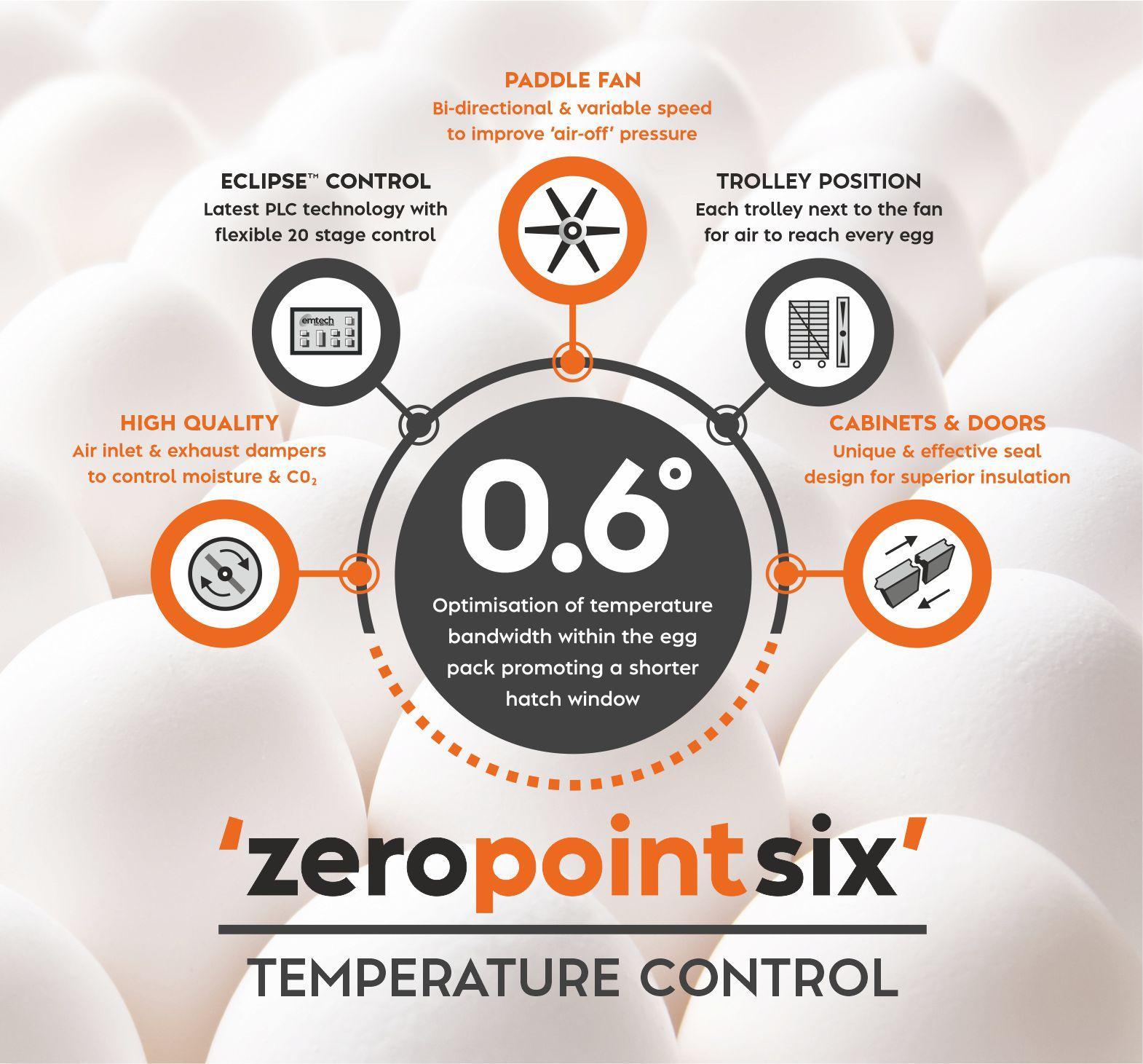

How do we achieve this?

EmTech incubator cabinets are different – they do not use an aluminium framework which can act as a thermal bridge taking heat away from where it is needed and unbalancing the internal environment. EmTech use interlocking PIR panels that eliminate thermal losses, cold air pockets and condensation while also providing 30% better thermal insulation than most other systems.

The layout of all EmTech incubators with only one trolley positioned, end-on, each side of the central fan gives the best airflow to every single egg regardless of where it is positioned within the trolley.

The bi-directional paddle fan has a unique tapered design which significantly improves the ‘air-off’ pressure and subsequently air velocities through the eggmass. The ability to change direction and vary the speed of the fan is significant to ensure that air reaches every corner of the egg pack.

The EmTech setter has a high-quality air inlet and exhaust dampers along with an improved seal door seal design. This promotes good levels of moisture and early percentage concentration of CO2.

With the well-sealed cabinet offering superior thermal insulation properties, a unique paddle fan design and optimum trolley orientation we have created the foundation for the optimisation of heat transfer and temperature bandwidth within the egg pack. All achieved by good old-fashioned engineering principals.

Now for the clever bits

Now we couple our excellently engineered incubator with Eclipse™ controls and the latest in PLC technology that incorporates variable fan-speed and forward and reverse functionality. This now gives us the capability to not only adjust the speed and direction of the paddle fans in relation to heat loads, cooling loads but also to the stages of incubation.

The Eclipse also provides the capability for 20 stages of control and the flexibility to make changes to the system over the entire incubation period to transfer and on to the hatcher. With this fine control and the ability to regularly change the pattern of air flow, we now have all the tools to stimulate and promote heat transfer and the optimisation of the temperature bandwidth.

Why should you take temperature bandwidth seriously?

It surely makes sense that if all the chicks hatch around the same time they have all been exposed to exactly the same environmental conditions. Conversely, if the hatch window is wide it is a good indicator that the conditions within the setter vary considerably.

This can be due to many factors, but usually it is the lack of significant air movement in the extremities of the setter cabinet. This causes hot spots resulting in an accelerated development and exhausted, poorly conditioned, chicks. Or too much air movement that can cause cooler air pockets resulting in delayed embryonic development, insufficient air flow and a prolonged dragged out hatch which will stress these and the earlier hatched chicks.

EmTech probably has more hatchery industry experience than any incubator supplier operating in the world today. We have questioned every aspect of incubator and ventilation system design and have designed new systems that are producing remarkable results around the world.

Do you really know what your average hatch window is?

Do you measure your 18-day temperature spread?

You may be surprised at the answer…